Dongron has established itself as a leading provider of high-quality die cast automotive parts. With a commitment to precision, durability, and innovation, the company offers a wide range of die cast automotive parts that meet the stringent requirements of the automotive industry and beyond.

High-Quality Materials and Advanced Manufacturing Processes

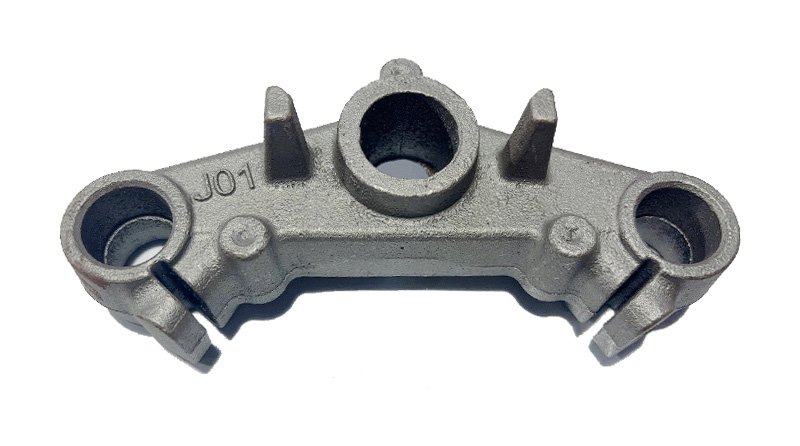

Dongron utilizes a variety of high-quality materials for its die cast automotive parts. These materials include aluminum, magnesium, and zinc alloys, which are chosen for their strength, durability, and resistance to corrosion. By selecting the best materials, Dongron ensures that its die cast automotive parts perform optimally and have a long service life.

The manufacturing processes employed by Dongron are state-of-the-art. The company uses die casting, sand casting, and investment casting methods to produce precision parts. These processes are supported by the latest technologies and sophisticated equipment, ensuring that every die cast automotive part is manufactured to the highest standards of precision and uniformity.

Strict Quality Control System

Quality is a top priority at Dongron. The company has implemented a strict quality control system that encompasses every stage of the production process. This system includes dimensional checks, material testing, performance assessment, and internal tests in accordance with industry standards. By adhering to these rigorous quality control measures, Dongron ensures that its die cast automotive parts meet the exacting specifications required by its customers.

Custom Die Cast Automotive Parts

One of the key strengths of Dongron is its ability to produce custom die cast automotive parts. The company has a dedicated team of experts who work closely with customers to understand their specific requirements. This collaborative approach ensures that each custom die cast automotive part is designed and manufactured to meet individual customer specifications.

Dongron's expertise in custom die cast automotive parts is evident in its ability to handle complex designs and high-precision requirements. Whether it's a unique engine component or a specialized transmission housing, Dongron can create custom die cast automotive parts that fit seamlessly into any vehicle.

Production Capacity and Versatility

Dongron's modern production facilities and streamlined procedures enable the company to handle both small and large orders with ease. This versatility means that Dongron can meet the demands of customers with varying production needs, from small-scale projects to large-volume orders.

The company's production capacity is further enhanced by its commitment to maintaining the highest quality standards. Dongron ensures that every die cast automotive part produced, regardless of the order size, meets the same stringent quality requirements.

Serving Multiple Industries

While Dongron's primary focus is on the automotive industry, the company's die cast automotive parts are also used in other sectors. These include aerospace, industrial machinery, and construction, where precise details and high-quality components are essential. Dongron's ability to produce die cast automotive parts that meet the specific needs of these diverse industries is a testament to its expertise and versatility.

Dongron's die cast automotive parts are the result of a commitment to quality, precision, and innovation. The company's use of high-quality materials, advanced manufacturing processes, and strict quality control measures ensures that its die cast automotive parts are reliable and durable. With a focus on custom solutions and the ability to handle large orders, Dongron is well-positioned to meet the needs of the automotive industry and beyond.

For customers seeking high-quality, precision-engineered die cast automotive parts, Dongron offers a comprehensive solution that combines expertise, versatility, and a dedication to customer satisfaction. Whether you need standard die cast automotive parts or custom solutions, Dongron has the capability and experience to deliver.